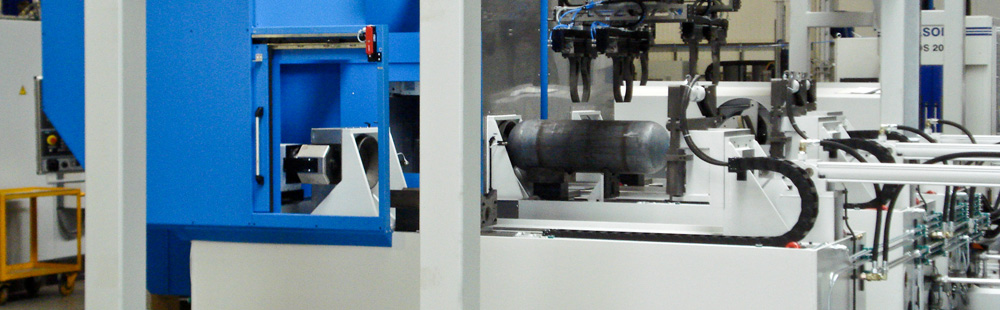

Double- spindle machining centers DSP

Machining example - brake disks:

Position-oriented perforation of ventilated brake disks offering the following advantages:

- Automatic identifi cation of different brake disks with different hole patterns

- Automatic turning of brake disk

- Identifi cation of ventilation ribs

- No multi-spindle boring tool-holders required

- Tool wear and breakage monitoring

- Cycle time: 49 seconds for 110 holes

Machining example - cone bearing rings:

Face turning and 12 x drilling/threading M18 x 1.5 in large cone bearing rings

- Automatic identifi cation and machining of pitch circles Ø100 to Ø170

- Tool wear and tool breakage monitoring

- Cycle time: 61 seconds

DOWNLOADS

https://www.youtube.com/watch?v=HVjmqeenpfU&feature=youtu.be