End machining centres EBZ

EBZ 60, Work piece lengths of up to 500 mm, with restrictions up to approx. 750 mm:

- Self-loading machine (pick-up principle)

- Easy and low-cost automation possible

- May be integrated into existing machine Systems

EBZ 60, Work piece lengths of up to 900 mm:

- Very fast feeding and discharge of work piece through the center or thorugh the hatch from above

- Simultaneous processing, two 3-aixs modules, each with a 6-station crown turret

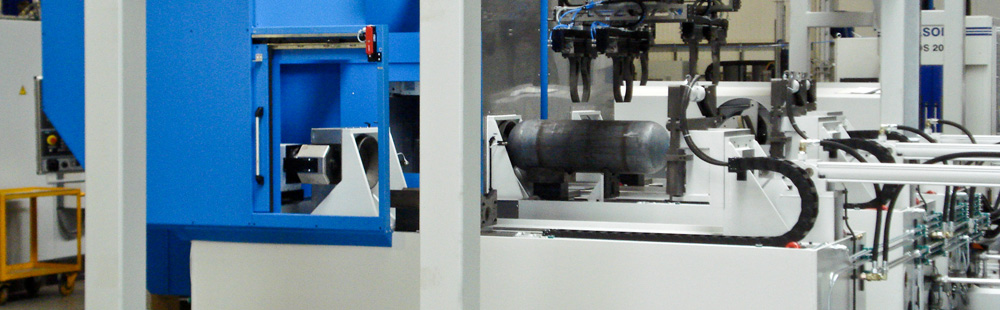

EBZ 200, Work piece lengths of up to 750 mm:

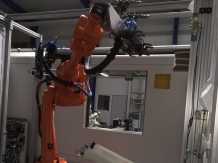

- End machining center with faster and more flexible loading and unloading by articulated robots or portal

- Two 3-axis modules, each with a fast and powerful 8-station crown turret

https://www.youtube.com/watch?v=fNf_kAu9Fbs

EBZ 250, Work piece lengths of up to approx. 2,500 mm:

EBZ 400, Work piece lengths of up to 4,500 mm:

- Modular machine concepts comprising multiple parts

- Two 3-axis modules are used to machine the ends independently of one another

- Loading by means of linear gantries, articulated robots, shop cranes

EBZ 400-CNG for machining CNG cylinder necks

- Cylinder dimensions up to Ø 400 and 2,500mm in length

- Cutting the length, core-hole boring, plain milling, outside and inside Ø, thread milling

- Cycle time: < 60 sec.

A machine is normally comprised of:

- Three machining stations

- Gantry loader with two vertical units

- Turning station with integrated vaccuum cleaning system

- Hydraulic clamping station

- Chip conveyor

- CNC control Siemens 840D solutionline

Short machining and auxiliary process times:

- Rapid traverse rates of up to 60 m/min of all axes

- Simultaneous machining possible resulting, ideally, in halving of machining times

- Revolver indexing time < 1 sec.

High flexibility:

- Tailored to the manufacturing job to be handled

- One-stop solutions for machines, loading devices and automation components, i.e. gripping assemblies, magazines etc., starting from the idea via design up to fabrication.

Varied optional devices for optimal adaptation:

- Various tool carrier systems and magazines

- Selectable tool holders

- Tool breakage control

- Minimal quantity lubrication or cooling lubricant system with band filter, also as optional high pressure version up to 90 bar

- Tool and process monitoring

- Customized automation components

- Measuring sensors

- Work piece-specific collet chuck

- U-axis

DOWNLOAD