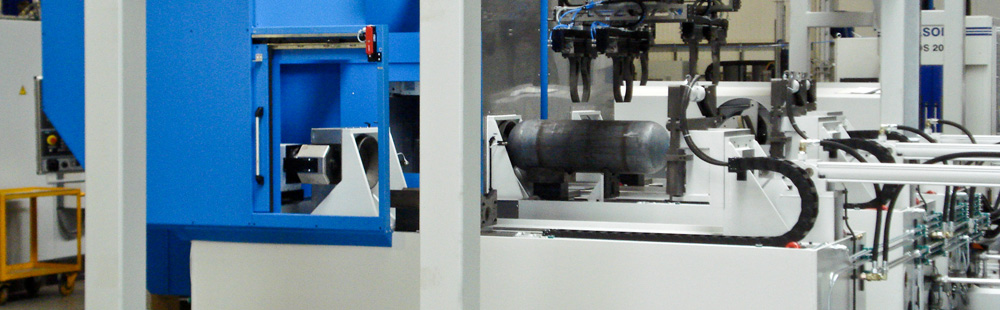

Vertical Turning Centers DS & DZS

Vertical Turning Centers DS

CONCEPT

Very high rigidity thanks to:

- Separate x- and z-slides (no compound rest slide)

- Machine top designed as welded monoblock filled with polymer concrete

High thermal stability thanks to:

- Cooled motor spindle

- Controlled fume exhaust

- Chip conveyor

Short ancillary process times:

- Rapid traverses of up to 60 m/min at high accelerations; hydraulic weight counterbalance in the vertical axis

- Feed and removal of the workpiece at speeds of up to 120 m/min, i.e. less than 6 seconds for loading and unloading the spindle

- Turret indexing time < 1 sec.

High flexibility:

- Tailored to the manufacturing job to be handled

- One-stop solutions for automation components, i.e. linear gantries, manipulators, gripper assemblies, magazines etc. starting from the idea via design up to fabrication

OPTIONS

- Automation system tailored to the technology applied

- Integrated measuring station inside turret, working area or on the outside

- Minimal quantity lubrication

- Tool and process monitoring

- Driven tools

- And many other features

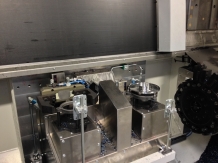

Vertical Turning Centers DZS

Our vertical turning centers DZS are available in 5 sizes and can be equipped with one spindle, two spindles, and with or without additional machining devices for high-performance milling, hob peeling (gear cutting), shaping, engraving and other machining methods.

The centers may be operated with two independent compound slide rests enabling parallel machining at the same time. The longitudinal slide moves along three linear guides and is equipped with a linear drive providing high stability together with high dynamics.

CONCEPT

Short auxiliary process times:

- Linear motor and three guides for the longitudinal slide

- 100 m/min and 5 m/s² on the X-axis

- Highly dynamic drives for the main spindle and the Z-axis

- Turret indexing time < 1 sec.

High flexibility:

- Tailored to the manufacturing job to be handled

- One-stop solutions for automation components, i.e. linear gantries, manipulators, gripper components, magazines, conveyor belts etc. starting from the idea via design up to fabrication

OPTIONS

- Installation of additional machining units

- Automation system tailored to the technology applied

- Integrated measuring station inside turret, working area or on the outside

- Tool and process monitoring

- Driven tools

- And many other features

DOWNLOADS